Slot Die Applicators

ITW Dynatec's PUR hot melt applicator and slot applicator technology provides industry-leading solutions for demanding manufacturing requirements including; precision metering, wide-web application, continuous & intermittent, and curtain coating technology.

|

APEX™ High Speed Slot Die

Quick Specs

- Precise high speed intermittent adhesive pattern

- Perfect for narrow web, contact coatings

- Clean adhesive cut-off at high speed

- Die lip design prevents build-up of unwanted materials

- Self-cleaning die lips permit the use of a variety of adhesive viscosities

- Easy system integration due to its compact design

|

|

Equity™ Continuous Slot Dies

Quick Specs

- Exceptional Value in a Slot Die Head

- Excellent Cross Web Adhesive Distribution

- Quick Change Slot Nozzle

- Modular Sections Permit Width Expansion in 50mm Increment

- Custom patterns in minutes with easy-cut shims provide exception flexibility.

|

|

CrossCoat™ Precision Metered Die

Quick Specs

- Non-contact application

- Ideal for heat sensitive materials

- Patented recirculation minimizes adhesive degradation

- Cross-web accuracy of +-5%

|

|

|

|

|

|

|

| |

|

|

|

|

|

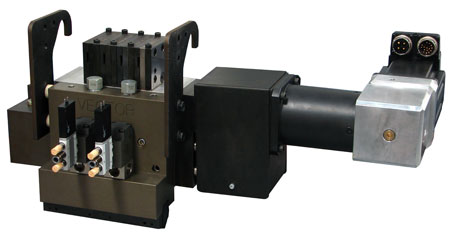

Vector Metered Hot Melt Slot Applicator

Quick Specs

- 0.5% Cross-web accuracy.

- Continuous and intermittent application

- Standard widths of 100mm, 200mm, 300mm, 400mm, 500mm and 600mm.

- Capable of providing individual metered flow output to each module.

- Slot applicator shares a common pump base with the spray and metering station.

|

|

|

BF Marathon Slot Applicator

Quick Specs

- Standard air open/air close module provides positive shut-off and on-cycle

- Platinum sensor provides better temperature control over nickel sensors

- Quick-clamp system for easy mounting

- Brass .004 shims included (set of 5)

- Built-in, heated filter has the largest surface area on the market, resulting in

longer filter life and less nozzle clogging

|

|

|

|

|

|

|

|

|

Twin Coat™ Non-Contact Dual Slot Die

Quick Specs

- High-precision non-contact applications

- Wide web coatings

- Crystal clear adhesive films

- Ultra-thin coatings at high speed

|

|

|

|

|

|

|

|

|

|

|

|